Hershey’s Syrup: Chocolate Goodness in a Tin

Introduction

It wasn’t until 1926 that Hershey Chocolate Company began manufacturing and marketing chocolate syrup. When Hershey’s Syrup was first introduced, it was marketed to commercial users (i.e. bakers, soda fountains, restaurants). Commercial chocolate syrup was marketed in two strengths: single and double. Single strength was promoted for use in soda fountain pumps for making carbonated beverages. Double strength was used for use as a topping and in milk drinks.

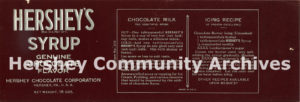

In late 1928, salesmen’s requests led the company to package and market Hershey’s single strength chocolate syrup for home use. It was packaged in two sizes: 5 ½ oz. and 18 oz. metal tins.

Production

Milton Hershey believed in being as self-sufficient as possible. He built his own power plant to provide electricity to run his factory and his town. He established sugar mills in Cuba to assure that he would have enough sugar for his milk chocolate bars and set up a print shop in the factory to print his own labels. Hershey Chocolate Company even manufactured its own metal containers for Hershey’s Cocoa. However, when Hershey began producing chocolate syrup, the company decided to purchase the cylindrical cans. It wasn’t until 1956 that Hershey began manufacturing their own syrup cans. Howard Phillippy, a plant engineer, led the effort to install the needed machinery. In his oral history interview, he explained how Hershey Chocolate factory began manufacturing its own syrup cans:

I well remember the way we got into making the syrup can was, at that time… I was in the design area. Whereas we never bought anything without it going through the formal purchasing department, I was pretty free, and if there was anything engineering-wise, production equipment-wise, the sales reps would invariably be referred to me. So one of these sales representatives working for Baldwin-Lima- Hamilton can-making machinery company had stopped in because they knew that Hershey was making their cocoa cans. Hershey was making cocoa cans before my time. We did buy improved machinery during my tenure there, but they were making cocoa cans before my time, for years back.

Now then, this can machinery representative, knowing that Hershey made their own cocoa cans, came around. He just wanted to see was there anything that he could offer from the standpoint of equipment improvement or did we need any help and that sort of thing. It was while he was there, he learned that we are buying our syrup cans, and he asked, “Gee,” he said, “why wouldn’t you make your own?”

I said, “I don’t know. The subject never came up, not in my time, anyhow. I don’t know really why we aren’t.”

He said, “Well, how many cans do you make a year?”

Well, we were making–let me say it was 70 million cans by that time. He said, “If you make 20 million cans a year, it would pay you to make your own.”

And I just said, “Well, we have no idea. How many people would it take to operate? What kind of machinery do we need?”

He said, “I’ll give you a list of the machinery you would need and approximately what kind of attendants you’d need.”

He supplied me with that, and on that basis, I went to–Lou Smith was then my superior. He was VP of engineering. I went to Lou and we, together, saw the great possibilities in this thing… Earl Lehman was the comptroller of Hershey Chocolate at that time. I remember taking the figures of the cost of the machinery, the cost of the whole project up to him, and he ran it through the cost process, and I know he said, “My goodness, we can’t afford not to make these.” His figures that he came out with showed that we would realize the cost of the equipment in a year and a half. He was saying, “Gee, how long is it going to be to get delivery of the machinery?” It was like nine months or more. As I recall, going into the business, buying all the machinery, was less than $1 million at that time. [Laughter] It was about 1956. The cost of all of that machinery, for two lines of manufacturing of the entire syrup can, was less than $1 million. The cost savings would be realized in a year and a half.

Marketing

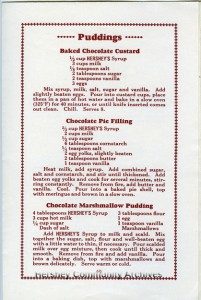

To help introduce the new product to consumers, Hershey Chocolate hired a public relations/marketing firm, N.W. Ayer & Son, to help with the launch. Hershey also hired a noted home economist, Caroline King, to develop 12 recipes using syrup. The recipes and syrup samples were distributed to “home institutes” and magazines, including Good Housekeeping Delineator, People’s Home Journal, McCall’s Magazine, Women’s Home Companion, Liberty and Conde Nast Publications. Initial results were positive and publications printed recipes and articles about Hershey’s new product.

In 1934 the 18 oz. size was reduced to 16 oz and marketed as a 1 pound tin. Labels incorporated the iconic Hershey block letter design.

From tin to plastic

Hershey continued to make its own syrup cans until 1979 when the factory began packaging Hershey’s syrup in 24-ounce plastic bottles.